Sankei B-RUBBER

B-RUBBER is Sankei’s solution to provide a sustainable source of natural rubber.

For use in products such as elastic and it can be traced from the rubber tree plantation source, to the finished produced elastic.

What is natural rubber and is it actually sustainable?

Natural rubber is produced by tapping around the trunk of an adult Hevea tree, collecting the sap called latex and then coagulating it with acid. This solidified product is called natural rubber.

Problems and challenges faced with the natural rubber business.

Environmental

The global demand for natural rubber, driven mainly by the motorization industry, has increased almost threefold in the past 4 decades. In response to this demand, the procurement practice often entails illegal deforestation, forest destruction and ecological deterioration.

Labour

Production of natural rubber is mostly done by an estimated 6 million small-scale farms in southeast Asia. Because many of these farms are maintained by poor people, they tend to breach human rights, through utilization of child labor, unfair labor and other illegal practices.

Economy

These small farms are laden with challenges like poverty, inefficient production practices due to lack of knowledge and experience in rubber production and the demand for more environmental requirements, combined with a lack of eco-consciousness.

What is industry doing to ensure that natural rubber is sustainable?

In 2018 the GPSNR (Global Platform for Sustainable Natural Rubber) was established.

As well as ourselves, this includes companies such as 18 high profile automobile and tyre manufacturers, which are major consumers of natural rubber, to create a sustainable society and will hold seminars to offer protection of natural resources and with the farmers’ participation.

What is SANKEI doing to ensure that natural rubber is sustainable?

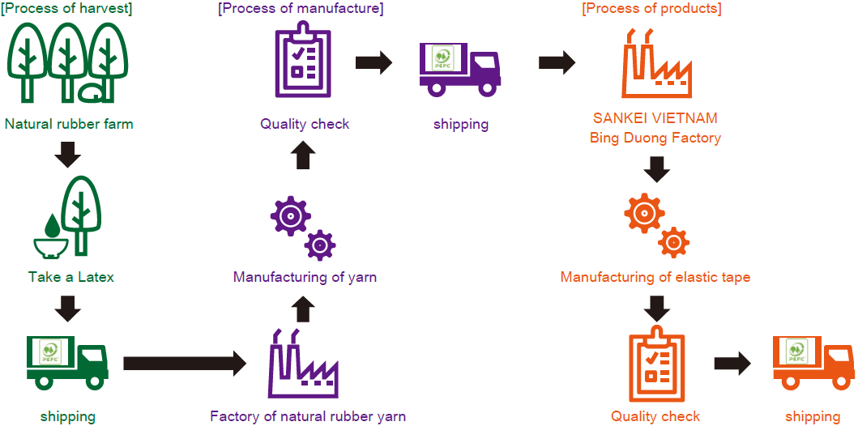

ITOCHU (Sankei’s mother company) developed an app, that allows farmers to register and manage raw materials with a QR code, which provides traceability throughout the distribution and production chain.

In collaboration with a government backed rubber plantation in Vietnam, Sankei has established a fully traceable natural rubber procurement scheme, the first of its kind amongst flat rubber manufacturers (elastic producers).

In order to achieve transparency throughout the flat rubber procurement process, we independently registered the rubber plantation, the yarn manufacturer and *Sankei (Vietnam) Co., Ltd. Binh Duong Branch as PEFC certified sites.

*https://sunlinesankeiyokohama.com/vietnam-elastic-factory

About PEFC (Program for the Endorsement of Forest Certification).

PEFC is a NGO forest certification program established in Europe in 1999 which has developed into an international certification organization, designed to exchange certificates with other forest certification frameworks around the word.

As of March 2021, 55 nations are PEFC members and more and more countries such as China, Japan and Vietnam are joining the framework, enabling Sankei to obtain certificates in every phase of its rubber production practise.

As of June 2019, over 300 million hectares of forests have been certified by PEFC, establishing PEFC as the world’s largest forest certification system and 11,741 business practices have received CoC Certification across the world.

Sankei in collaboration with our partners, realizes a unique traceability framework by obtaining CoCs for subsequent processing and distribution phases to cover the entire production practise.

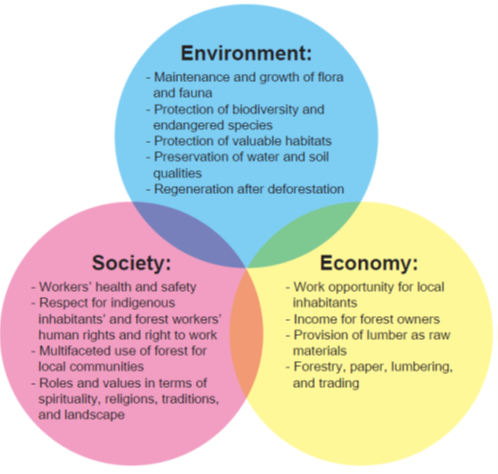

The three pillars of sustainable forest management standards.

Combing all these efforts and by keeping all off these aspects in good balance, forests can be maintained sustainably.